Choosing Thread Types for Sewing Success

When you're starting a new sewing project, it's easy to get caught up in picking the perfect fabric and pattern. But there's another choice that's just as crucial, if not more so: selecting the right thread types for sewing. It might seem like a small detail, but thread is the literal glue holding your entire creation together.

Get it right, and your seams will be strong, smooth, and practically invisible. Get it wrong, and you're in for a world of puckered seams, broken stitches, and projects that fall apart after a few wears. It’s the kind of thing that makes you want to give up sewing altogether!

Why The Right Thread Is Your Most Important Tool

It’s tempting to think of thread as just... well, string. But every spool you see has been engineered with specific properties. Some are built for strength, others for flexibility, and some are designed purely for their beautiful finish. Using the wrong one is one of the most common reasons both beginners and seasoned sewists run into frustrating problems.

Often, we blame the sewing machine when things go wrong, but a mismatched thread is frequently the real culprit. Have you ever experienced these issues?

- Puckered or Wavy Seams: This is a classic sign that your thread and fabric aren't getting along. Maybe the thread has too much stretch for your crisp cotton, or not enough give for a knit.

- Broken or Skipped Stitches: If your thread is constantly snapping or shredding, it could be too thick for the needle you're using.

- Seam Failure: This is the most heartbreaking one. If the thread is weaker than the fabric, it’s only a matter of time before a seam gives way under stress.

The Hidden Framework of Your Creations

Think of it like building a house. You wouldn't use tiny nails to join heavy structural beams; you’d need industrial-strength bolts. Sewing works on the same principle. Your thread is the hidden framework, and it needs to be just as thoughtfully chosen as your fabric. A delicate silk thread that’s perfect for a sheer blouse would snap in a second on a pair of rugged canvas trousers.

The secret to a professional-looking and long-lasting garment lies in the harmony between fabric, needle, and thread. When these three elements work together, the result is a strong, smooth, and beautiful seam that performs exactly as intended.

To really get this right, you need to understand your options. While decorative threads are designed for visual appeal (this comprehensive guide on different types of embroidery floss is great for that), sewing thread is all about performance and strength.

Quick Guide to Common Sewing Thread Types

To give you a head start, here's a quick look at the most common threads you'll find and what they're best used for.

| Thread Type | Best For | Key Characteristic |

|---|---|---|

| All-Purpose Polyester | The go-to for most projects, from wovens to knits. | Strong, durable, with a little give. |

| Cotton | Quilting, piecing, and natural fibre fabrics like cotton/linen. | No stretch, soft finish, presses well with heat. |

| Silk | Fine fabrics like silk and wool; also for tailoring/basting. | Very strong yet fine, with a beautiful natural lustre. |

| Heavy-Duty | Upholstery, canvas, denim, and outdoor gear. | Extra thick and engineered for extreme strength. |

This is just a starting point, of course. Understanding the why behind each choice is what will truly elevate your sewing.

What You Will Learn in This Guide

This guide is here to demystify the world of sewing thread. We’ll break down everything you need to know, from the workhorse that is all-purpose polyester to specialty threads for tricky fabrics. You’ll even learn how to read those confusing numbers on the spool so you can understand thread weight.

By the end, you'll be able to walk into any fabric shop with confidence, knowing exactly how to pick the perfect thread for your fabric and machine. Your projects will not only look better, but they'll be built to last.

Working With Natural Fibre Threads

When you start exploring the vast world of sewing threads, you'll find that natural fibres are the true classics. They’ve been at the heart of sewing for centuries, and for good reason. Threads made from plants and animals just behave differently than their synthetic counterparts—they have a character that synthetics can only try to imitate.

The real magic of using a natural fibre thread is in how it works with your fabric. Think of it as matching like with like. When your thread and fabric come from a similar source, they react to washing, ironing, and daily wear in the same way. This harmony ensures your project ages beautifully, without seams puckering or giving out prematurely.

Here in Canada, natural fibres, especially cotton, have a devoted following among home sewists and quilters. It’s a testament to the reliability and feel of these traditional materials. For more on sewing thread market trends, you can check out platforms like researchandmarkets.com.

Cotton Thread: The Quilter’s Best Friend

Cotton is easily the most popular natural fibre you'll find in any sewing basket, and it’s an absolute superstar in the quilting world. If you're sewing with 100% cotton fabric, using 100% cotton thread is a golden rule for many seasoned sewists.

Why? Because cotton thread has very little give. This is a huge plus for patchwork, as it helps you create perfectly flat seams and precise blocks without any stretching or distortion. Plus, it can handle a hot iron just like your cotton fabric can, meaning you can press your seams open without worrying about the thread melting.

Key Insight: The biggest advantage of cotton thread is that it wears at the same rate as cotton fabric. Decades down the line, the thread won't be tougher than the fabric it's holding together, which prevents it from cutting through the fibres of your treasured quilt.

Its lovely matte finish also helps it sink into the fabric, making your stitches look like they’re a part of the textile itself. Whether you’re piecing a quilt or topstitching a simple sundress, a good quality cotton thread, like this beautiful Gütermann Cotton thread, just feels right.

Silk Thread: Luxurious and Surprisingly Strong

If cotton is the reliable workhorse of the sewing room, then silk is the elegant racehorse. Spun from the cocoons of silkworms, silk thread is famous for being incredibly strong despite its fine diameter. It’s thinner than most other threads but packs a serious punch in the strength department, all while having a gorgeous natural sheen.

This blend of delicacy and durability makes it the go-to choice for working with high-end fabrics.

- Fine Fabrics: When you're sewing with silk or wool, using silk thread creates seams that are strong yet barely there, preventing bulk.

- Tailoring: Professionals love silk thread for hand-worked buttonholes because it creates a smooth, durable, and beautiful finish.

- Basting: It glides through delicate fabrics without leaving holes or marks, making it ideal for temporarily holding pieces together in high-end garment making.

Silk also has a bit of natural elasticity, which gives your seams some flexibility—perfect for areas that might be under a little stress. While it’s certainly a more premium choice, its performance on delicate materials is second to none. And as a nice little bonus, its smooth texture means less lint builds up in your sewing machine.

Getting to Know Modern Synthetic Threads

While we all love the classic feel of natural fibres, the sewing world today really spins on synthetics. Think of these threads as the engineered powerhouses in your sewing kit. They're built for strength, resilience, and a kind of versatility that natural fibres just can't always deliver. If you've ever sewn a garment, you've almost certainly used a synthetic thread—and for very good reason.

Unlike cotton, which grows in a field, synthetic threads are born in a lab. This means their properties can be tweaked and perfected. We can create threads that laugh in the face of mildew, refuse to shrink, and stand up to the harsh UV rays that make natural fibres brittle. They're the reliable workhorses for just about everything, from your favourite t-shirt to heavy-duty outdoor gear.

Polyester: The Ultimate All-Rounder

If you could only have one type of thread in your collection, all-purpose polyester would be it. It’s the go-to for the vast majority of sewing projects because it hits that sweet spot between strength and flexibility. It has just a little bit of stretch, which makes it a dream to work with on both woven and knit fabrics.

That tiny bit of give is polyester’s secret weapon. It lets the seams on your clothes move with you instead of snapping—a classic problem when you use a no-stretch cotton thread on a stretchy knit. A good quality polyester thread is tough, creates way less lint than cotton, and comes in an endless rainbow of colours.

You'll generally run into two main kinds:

- Spun Polyester: This is made from shorter polyester fibres that are spun together into a single thread. This gives it a slightly fuzzy look and feel, a lot like cotton, making it a fantastic general-purpose thread for most garment sewing.

- Core-Spun Polyester: This is the premium stuff. It’s built with a continuous, super-strong polyester filament at its core, which is then wrapped in a soft spun polyester. This combo gives you the incredible strength of the core and the easy sewability of the spun wrap. It’s a favourite for high-stress seams, like the ones on a sturdy pair of jeans.

Nylon: The Strength Specialist

When your project absolutely has to be tough, nylon thread is what you reach for. Picture nylon as polyester’s stronger, more rugged older sibling. It’s famous for its incredible strength, resistance to abrasion, and superior elasticity, making it the clear winner for items that will take a serious beating.

Because it's so durable, you'll see nylon used in projects where a failed seam just isn't an option.

Pro Tip: Nylon thread is the industry standard for high-stress jobs. Its unique blend of strength and stretch allows it to absorb shock and movement, which is why it's trusted for everything from rock-climbing gear to automotive upholstery.

You’ll want to grab a spool of nylon when you're working on:

- Upholstery and home décor projects

- Leather goods like bags, wallets, and shoes

- Outdoor gear such as tents and backpacks

- Heavy-duty materials like canvas or vinyl

One thing to keep in mind is that while some nylon is UV resistant, standard nylon can get weak after a lot of time in the sun. For outdoor projects, always look for a "bonded nylon." It has a special coating that protects it from friction during high-speed sewing and adds an extra layer of durability.

Navigating Specialty Synthetic Threads

Beyond those everyday workhorses, the synthetic family has some unique members designed for specific looks or jobs. These specialty threads can be a little finicky sometimes, but the stunning results are well worth the extra patience.

Metallic Threads

These threads are all about the sparkle. They're typically made with a synthetic core (usually nylon or polyester) that's wrapped in a super thin layer of metallic foil. They look incredible, but that delicate construction means they can sometimes shred or break.

To sew with them successfully:

- Switch to a Metallic or Topstitching needle. These have a larger eye, which means less friction on the thread.

- Slow your machine down. Sewing at high speed can create heat that causes the delicate thread to snap.

- Lower your top tension a little. This helps the thread flow more smoothly through the machine.

Invisible Threads

Often called monofilament thread, this is basically a single, fine strand of nylon or polyester that looks a lot like a fishing line. It comes in clear for light fabrics and smoke for dark fabrics. It's the secret to "invisible" machine quilting or appliqué where you want the stitches to disappear. Just like with metallics, using a needle with a bigger eye and easing up on the tension will make your sewing experience much smoother.

Making Sense of Thread Weight and Size

Walking into a sewing shop and looking at a wall of thread can feel a little intimidating. You’ll see spools marked with numbers like 40 wt, 50/3, and 120d/2, and it's easy to wonder what it all means. But don't worry—cracking this code is the secret to getting beautiful, strong stitches, and it's much simpler than it looks.

The most important thing to remember about thread weight is that it works in reverse. It's a bit strange at first, but you'll get the hang of it quickly.

A lower number means a thicker, heavier thread.

A higher number means a finer, lighter thread.

Think of it this way: a bold 30 wt thread is designed to be seen, making it perfect for topstitching on jeans. On the other hand, a delicate 100 wt thread will sink into the fabric, becoming almost invisible.

How to Read a Spool

So, what are you actually looking at on the label? While there are a few different sizing systems out there, the one you'll see most often in home sewing is the Weight (wt) system. It's a simple, direct way to understand a thread's thickness.

Sometimes, you'll see a second number after a slash, like in "50/3". This little detail tells you about the thread's construction and is a great clue to its quality.

- The First Number (the 50): This is the thread's weight. In this example, it's a standard, versatile 50 wt thread.

- The Second Number (the 3): This is the ply. It tells you how many individual strands of fibre were twisted together to make the finished thread. A 3-ply thread, like this one, is made of three strands, which gives it excellent strength and a smooth, balanced finish.

Why does ply matter? A thread made from multiple plies is far less likely to shred or snap, especially when your machine is running at full tilt. You might occasionally see other systems like Tex or Denier, especially on industrial or serger threads, but for most of us, sticking to the "wt" system will get you exactly what you need.

Matching Thread Weight to Your Project

This is where the magic happens! Picking the right thread weight for your project can be the difference between a frustrating sewing session and a flawless finish. If your thread is too thick for the needle, it will shred and break constantly. If it's too fine for your heavy-duty denim, the seams just won't hold up.

Here’s a simple chart to help you match the most common thread weights to the job at hand.

Common Thread Weights and Their Uses

This table is a great starting point for choosing the right thread. It breaks down the common weights and shows you which projects and needle sizes they pair with best.

| Thread Weight (wt) | Description | Common Uses | Recommended Needle Size |

|---|---|---|---|

| 30 wt - 40 wt | Thick & Strong. Creates visible, bold stitches. | Topstitching, quilting, buttonholes, bag making, and decorative stitches. | 90/14 or 100/16 |

| 50 wt | The All-Purpose Standard. Strong yet not bulky. | General garment construction, patchwork piecing, and machine quilting. | 80/12 or 70/10 |

| 60 wt - 80 wt | Fine & Delicate. Blends seamlessly into fabric. | Appliqué, heirloom sewing, lingerie, and fine fabrics like silk or batiste. | 70/10 or 60/8 |

| 100 wt | Ultra-Fine (Silk Finish). Almost invisible. | English paper piecing, delicate lace work, and "stitch-in-the-ditch" quilting. | 60/8 (Microtex) |

Choosing the right thread is about setting yourself up for success. Once you get the hang of it, you'll find yourself reaching for the right spool without a second thought.

A fantastic workhorse for any sewing kit is a quality 50wt 3-ply polyester thread, which can handle a massive range of sewing and quilting tasks. By taking a moment to check the weight, you’re not just buying thread—you're choosing the perfect tool for the job. It's a small step that makes a huge difference in creating strong, beautiful, professional-looking projects.

How To Match Thread To Fabric And Needles

Getting that perfect, professional-looking stitch is a bit like conducting an orchestra. Every player—your machine, fabric, thread, and needle—has to work in perfect harmony. If even one is out of sync, you don't get beautiful music; you get a tangled mess of skipped stitches and puckered seams. This is where so many sewing frustrations start, but it’s also where you can gain the most control.

The good news is that matching these components is pretty straightforward once you understand a few core principles. It all starts with one simple rule of thumb that will instantly level up your results and save you countless headaches.

Start With The Golden Rule Of Fibres

The most reliable way to pair thread and fabric is to match fibre types. Think of it as keeping families together—materials from the same family just get along better. They act in similar ways when you wash, dry, iron, and wear them.

A cotton thread is the natural partner for cotton, linen, or other plant-based fabrics. A polyester thread is right at home with synthetics like polyester, nylon, or acrylics. This simple choice ensures your thread and fabric will age gracefully together, shrinking or stretching at a similar rate and preventing your seams from puckering over time.

Of course, a good all-purpose polyester is a fantastic workhorse for most fabrics. But when you’re aiming for truly impeccable results, especially with natural fibres, sticking to this rule is best practice.

Aligning Thread Weight With Needle Size

Once you’ve picked your thread fibre, the next critical partnership is between the thread's thickness (its weight) and the size of your sewing machine needle. This relationship is non-negotiable if you want to sew smoothly. Trying to force a thick thread through the tiny eye of a small needle is a recipe for disaster.

Imagine trying to jam a thick rope through a small keyhole. It’s going to fray, shred, and probably get stuck. The exact same thing happens with your thread. This friction is the number one cause of thread breaking and shredding mid-seam. On the flip side, using a super-fine thread with a huge needle creates sloppy stitches and poor tension because the thread has too much room to wiggle around.

The Essential Takeaway: Your needle’s job is to poke a hole in the fabric just big enough for the thread to pass through without getting roughed up. A thicker thread needs a larger needle to make a bigger hole.

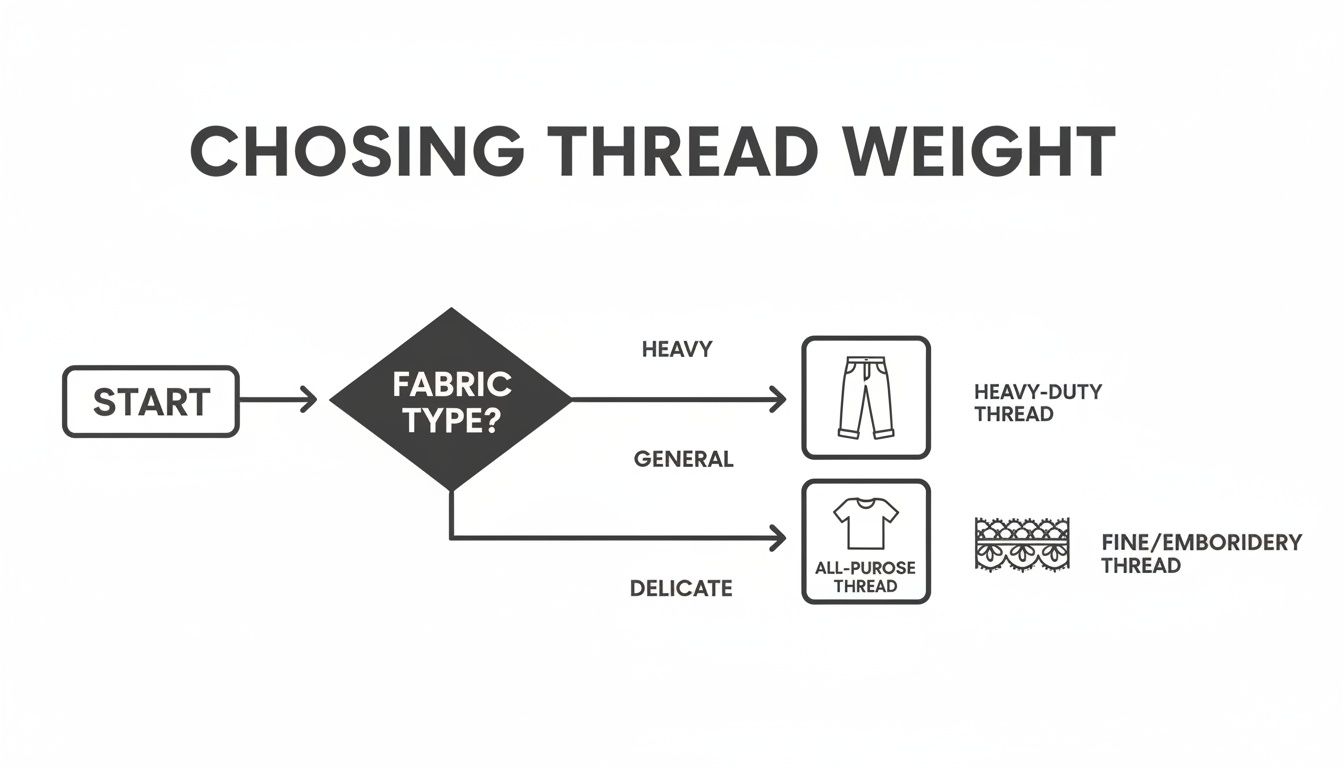

This flowchart walks you through a simple decision-making process for picking a thread weight based on your fabric.

As you can see, heavy fabrics demand a thicker, stronger thread, while delicate materials need a finer touch for stitches that blend in seamlessly.

Quick Pairing Guide For Success

To make life easier, here’s a quick-reference guide for pairing common thread weights with the right needle sizes.

- For Heavy-Duty Threads (30wt): You'll need a bigger needle, like a 90/14 or 100/16 Jeans or Topstitching needle. This gives that thick thread plenty of room to move through tough materials like denim, canvas, or multiple layers of fabric.

- For All-Purpose Threads (40wt-50wt): The standard 80/12 Universal needle is your best friend here. It’s the perfect middle-ground for the vast majority of sewing projects.

- For Fine Threads (60wt-80wt): Switch to a smaller needle, like a 70/10 or 60/8. When you're working with very delicate fabrics like chiffon or batiste, you might want a specialized needle. For example, Schmetz Microtex Sharp Needles are brilliant for creating precise, tiny stitches on fine materials.

Adjusting For Specialty Threads

Not all thread types for sewing are designed for putting things together. Specialty threads, like the ones used for sergers or embroidery machines, have their own unique jobs.

Serger thread, for instance, is usually a lighter weight (around Tex 27) and comes on big cones because a serger uses a lot of it to create those loopy overlock stitches. It’s engineered to be smooth and strong for that specific task but generally isn't meant for the high-tension, single-needle work of a regular sewing machine.

Embroidery thread, on the other hand, is all about looks, not strength. Its primary job is to add a beautiful sheen to decorative designs. While gorgeous, it just doesn’t have the durability needed to hold a structural seam together. Always use these threads for their intended purpose to make sure your projects are both beautiful and built to last.

Troubleshooting Common Thread Problems

Even when you’ve carefully matched your thread, needle, and fabric, things can still go wrong. It happens to everyone! A sewing machine is a finely tuned instrument, and one tiny thing being out of place can bring your project to a screeching halt. Think of this as your field guide to figuring out those frustrating thread issues without wanting to throw your machine out the window.

Most of the time, the fix is much simpler than you think. Instead of randomly twisting dials, we’ll walk through the likely culprits one by one.

Solving Thread Breaking or Shredding

There's nothing quite like the feeling of getting into a good sewing rhythm, only to have your top thread snap. Ugh. If your thread is shredding, fraying, or breaking, it's telling you one thing: there's too much friction or strain somewhere on its journey from the spool to the fabric.

Before you touch a single tension dial, run through this simple checklist. It solves the problem nine times out of ten.

- Change Your Needle: Seriously, start here. This is the #1 cause of shredding thread. A needle gets dull or develops a microscopic burr after just 8-10 hours of sewing, which is more than enough to snag and tear your thread apart.

- Rethread Your Entire Machine: Don't just fix the broken part. Pull both the top and bobbin threads out completely and start fresh. Crucially, make sure your presser foot is up when you thread the top. This opens up the tension discs so the thread can sit correctly where it belongs.

- Check the Thread's Path: Turn the spool and feel along its edges for any tiny nicks that might be catching the thread as it unwinds. Then, slowly pull the thread through the machine by hand. Can you feel it catching anywhere?

If you've tried all that and the problem persists, you might have a mismatch between your thread and needle. Trying to pull a thick thread through the eye of a needle that’s too small is a surefire way to cause shredding. You're essentially creating a traffic jam.

Pro Tip: Always, always suspect the needle first. A new needle is the cheapest and fastest fix for a huge range of sewing machine headaches. Think of it as the simplest solution hiding in plain sight.

Fixing Loops and Bird's Nests

Ah, the infamous "bird's nest"—that horrible, tangled mess of thread on the bottom of your fabric. It’s one of the most common sewing frustrations, and it’s a classic sign of a tension imbalance. But here’s the twist: even though the mess is on the bottom, the problem is almost always with your top thread.

What’s happening is that the top thread doesn't have enough tension to pull the bobbin thread up into the middle of the fabric. So, the top thread just hangs out on the bottom, forming messy loops with every stitch.

Here’s how to fix it:

- Rethread the Top: Yes, again! But this time, pay close attention and make sure that presser foot is lifted high. This is the most common reason for those dreaded loops.

- Double-Check Your Bobbin: Is it in the right way? Is the thread coming off in the correct direction? Every machine is a little different, so give your manual a quick look if you're not 100% sure.

- Give it a Quick Clean: Lint, dust, and tiny thread scraps love to build up in and around the bobbin case and tension discs. This gunk can physically block the parts from doing their job properly. A little brush-out can make a world of difference.

By patiently working through these steps, you can diagnose and solve the vast majority of thread issues and get back to what you love—sewing.

Your Sewing Thread Questions, Answered

Got a question about thread? You're not alone. Here are some of the most common queries we hear, with practical answers to help you get the best results on your next project.

Can I Use All-Purpose Polyester Thread For Quilting?

You absolutely can! Especially when you're piecing the quilt top together, a good quality all-purpose polyester thread is a fantastic, reliable choice. It's strong, handles machine stitching beautifully, and is a true workhorse for many thread types for sewing.

That said, many quilters are purists and will only use 100% cotton thread. Their reasoning is sound: cotton thread behaves just like cotton fabric. This means it will wear, wash, and even shrink at the same rate as the quilt itself over the years, creating a more cohesive and traditional final product.

Does Sewing Thread Actually Expire?

It certainly does. Thread doesn't have a stamped-on expiry date, but it definitely degrades over time. Exposure to things like sunlight, humidity, and even dust can make fibres brittle and weak, especially natural ones like cotton.

If you've ever had a thread that just keeps snapping in your machine for no reason, its age might be the culprit.

Here's a quick way to test an old spool: Unwind about a foot of thread and give it a sharp tug with your hands. If it snaps with barely any effort, it's past its prime. Tossing that spool will save you a ton of future sewing headaches.

What Is The Real Difference Between Sewing And Embroidery Thread?

Think of it like this: sewing thread is the structural beam, and embroidery thread is the decorative paint.

Sewing thread is engineered for strength and durability. Its entire purpose is to construct seams that will hold a garment or project together through stretching, washing, and general wear-and-tear.

Embroidery thread, on the other hand, is all about appearance. It’s designed to have a gorgeous lustre and sheen that makes decorative stitches and designs stand out. It simply doesn't have the strength needed for construction, and using it for seams will likely lead to them falling apart.

At All About Sewing, we know that the right thread is the unsung hero of every great project. From versatile all-purpose spools to specialty options for unique fabrics, we have the perfect match for you. Explore our collection at https://all-about-sewing-canada.myshopify.com and find exactly what you need to bring your vision to life.